-By Ron Engle-

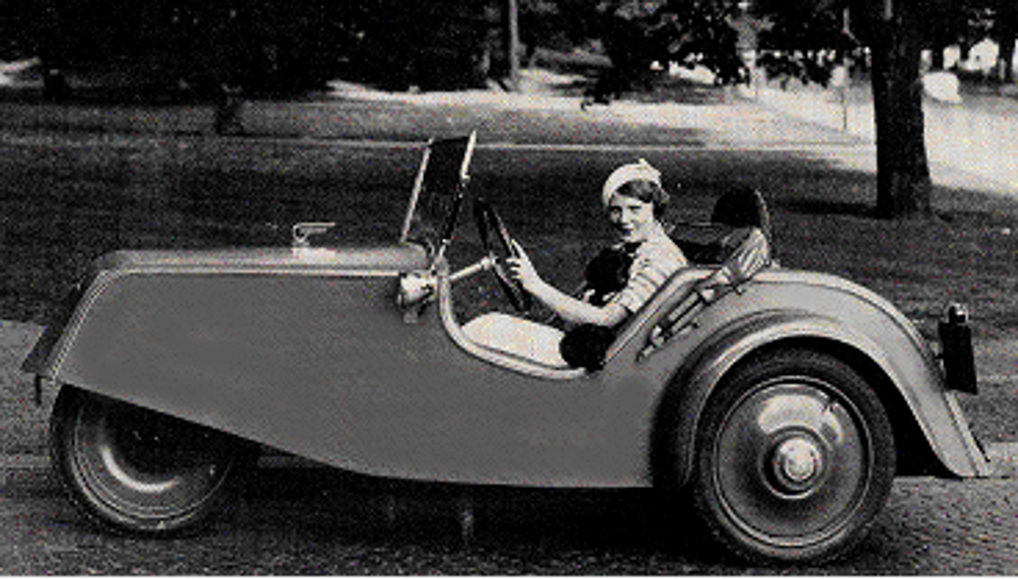

Carl F.W. Borgward had designed and built automobiles in Bremen, Germany, from the 1920s to 1961. One of his earliest designs in the 1920s, was a 2.2 hp three wheel motor cycle carrier called the “Blitzkarren” (the Lightning Cart) which later became a passenger car named the Goliath Pionier in 1931.

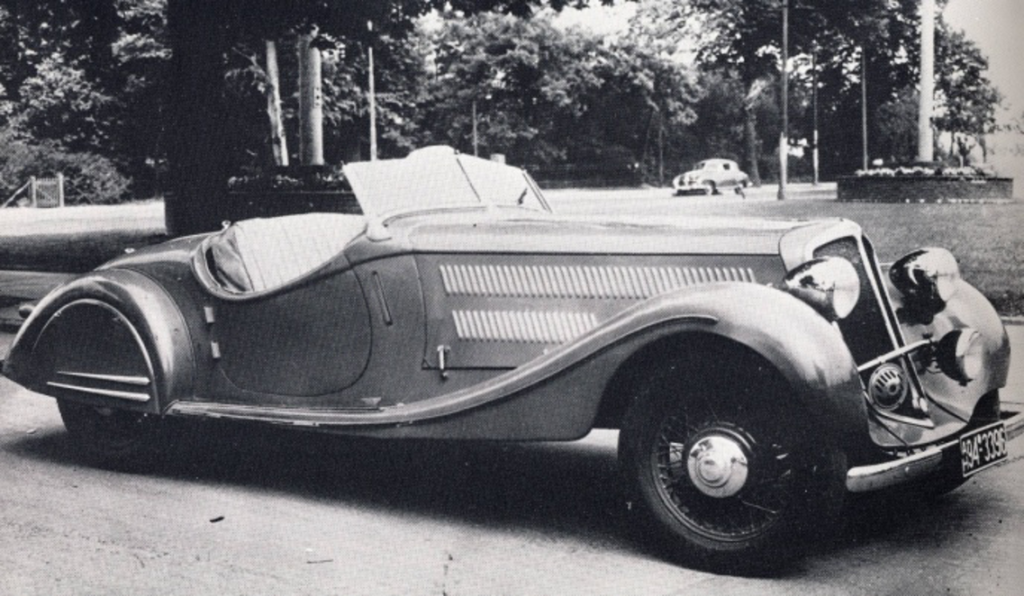

In 1934 Borgward introduced two new cars, the Hansa 1100 and 1700 both built until 1939. They were an immediate success, received great reviews from the press, and sales were so brisk that you had to wait six months for delivery. The Hansa was considered serious competition for the German automobile market leaders Opel, Ford, Adler, Hanomag, and Wanderer.

During World War II, production was switched to transport carriers, heavy trucks, and armored demolition vehicles. The plant was totally destroyed by allied bombing. In 1948-1949 raw materials in Germany were scarce and rationed. To gain an advantage, Carl Borgward divided his production into three separate companies with separate factories for each of his three automobiles – Goliath, Lloyd, and Borgward: the Goliath Werk GmbH, the Lloyd Maschinenfabrik GmbH, and the Automobil- und Motorenwerke Carl F.W. Borgward GmbH. All three remained privately owned by Carl F.W. Borgward.

By the mid 1950s, the Borgward Group, which included Borgward, Goliath, and Lloyd automobiles, was the second largest manufacturer of automobiles in Germany having produced over 500,000 units between 1948 and 1957. Borgward was the first German production car after World War II to use unibody construction. Borgward also produced highly successful racing cars—including the Borgward Rennsport RS, which broke dozens of international class records in mountain racing, Formula II, and stock. Stirling Moss raced a Cooper-Borgward (Cooper body, Borgward engine). In 1953, Borgward introduced the Hansa 2400 model.

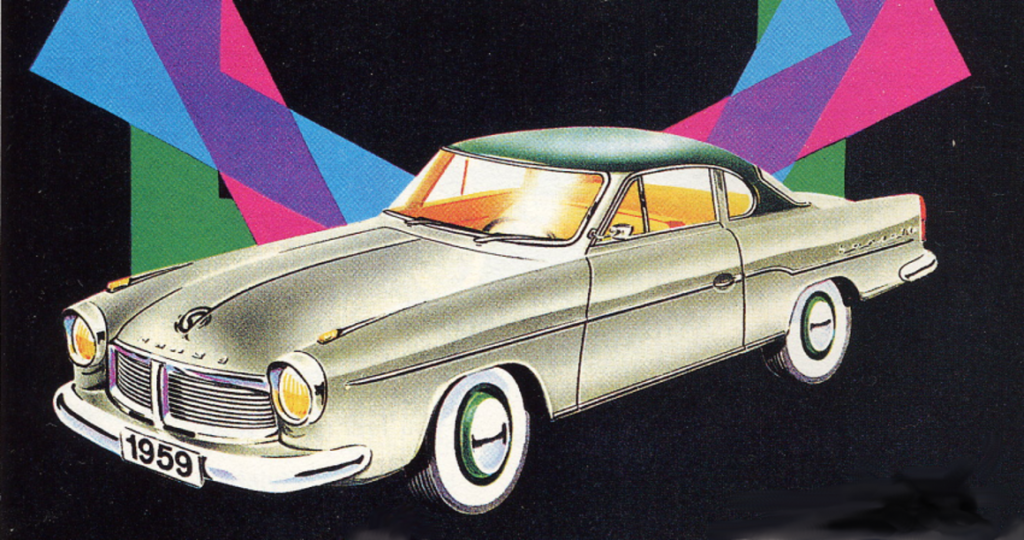

In 1957 the Borgward Group (Borgward, Goliath, and Lloyd) celebrated its 500,000th car off the assembly line to become the second largest German car manufacturer. Also in 1957 two more models were added to the Isabella line: the Isabella TS de Luxe and the Isabella Coupé. Over 202,000 in the Isabella line were eventually produced. According to a Borgward press release in 1959, the Borgward Group produced 107,500 vehicles: 46,164 Borgwards (3,090 exported in parts to Argentina), 43,174 Lloyds, and 15,072 Goliaths.

Borgward Automobiles Featured at the 2021 InterMarque Spring Kick-Off

Ron Engle’s Borgward Isabella Coupé

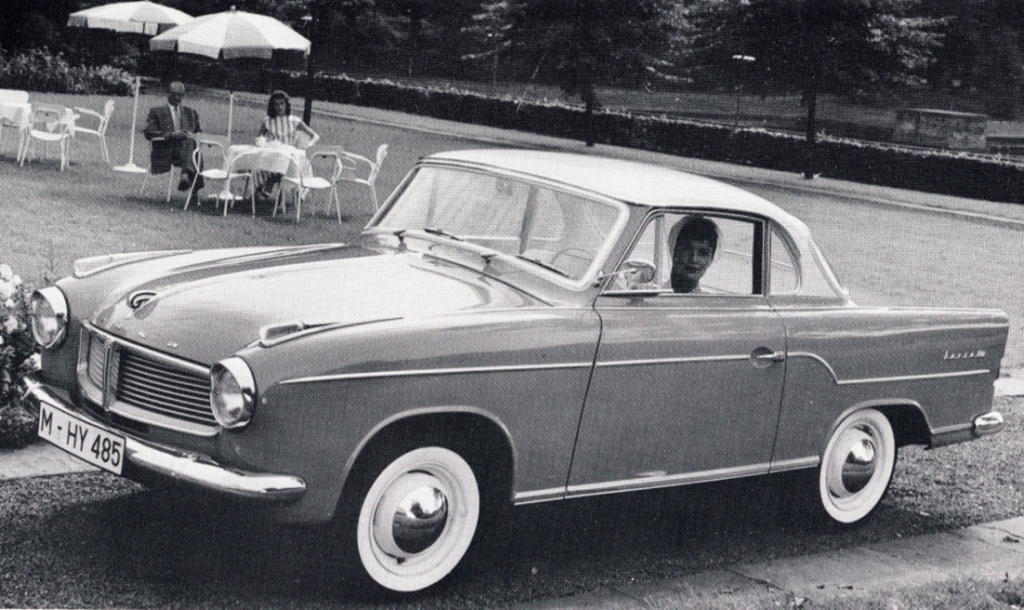

The Isabella Coupé was an instant hit with automotive critics and the public. Since its introduction in 1957, the Isabella Coupé has become an icon of automotive design and one of the most sought after German classic cars. Borgward designed the Coupé himself. Using the chassis, TS motor and many parts of the Isabella TS sedan model, the new factory tooling for production was minimal. Each Coupé was hand fitted, so that one door might not fit in another Coupé. The sweeping lines and curves with touches of chrome were very appealing. The interior was well equipped with sports car attributes. The Isabella Coupé was so revered that the Museum of Modern Art in New York displayed the car as a classic of automotive design in the 1970s.

The Isabella Coupé was powered by the TS inline four cylinder OHV 1.493 liter engine with a compression ratio of 8.2:1. Road and Track reported 82 BHP @ 5200 rpm with the 2 barrel Solex 32 PAITA carburetor. The 4 speed synchromesh transmission was “4 on the tree”. All Isabella models featured four wheel independent suspension and gas mileage ranged between 28 to 34 mpg.

The 1960 Coupé sold for $3695 in the United States. This was an expensive car considering that in that same year a new Ford Thunderbird sold for $3755 and a Corvette for $3872. Of the approximately 10,000 Isabella Coupés produced, about half of the sales were in the United States.

By 1959 there were over 500 dealers in the United States. From 1955 to 1961 there were approximately 60,000 Borgward Isabellas, Goliaths, and Lloyds sold in the United States. In 1959 alone, US sales totaled 16,409: 8,573 Borgwards, 3,422 Goliaths, and 4,414 Lloyds. This compares to 13,739 Mercedes and 2,268 DKW Auto Union (future Audi) for that same year. The Coupé proved to be especially popular in the United States where about half of the 10,000 produced were sold.

While both the smaller “compact” Goliath and “mini” Lloyd automobiles were sold and marketed under their own brand names, they were part of the Borgward Group. They had smaller engines and both were exported to the USA. Between 1955 and 1961, 176,000 Lloyd 600 (19 hp) and Lloyd Alexander (25 hp) two cylinder four stoke models were produced. The compact Goliath featured front wheel drive and was one of the first production cars with Bosch fuel injection. The 1958-59 Goliath Tiger’s 1100cc engine was a horizontally opposed 4 cylinder water cooled twin carburetor engine producing 63 hp.

Mike Gondek’s Goliath 1100 Kombi

The Goliath 1100 first appeared in March of 1957 at the Geneva Motor Show and was manufacture in Bremen at the Goliath-Werke part of the Borgward Group. Between 1960 –1961 Goliaths were also manufactured in Argentina. The Goliath brand seemed to be Carl Borgward’s experimental car with its advanced engineering concepts. It had a four stroke four cylinder 1094cc water cooled boxer engine. With the early 900E Goliath, Borgward experimented by being the first manufactured production car with fuel injection. Very few of the Goliath 900E models have survived.

Another experimental design featured the Saxomat automatic clutch option that was offered from 1959. Very few of these Goliaths with Saxomat made it to the USA. At some point, fins were added to the rear fenders, most likely a nod to the American market. The Goliath was originally offered in: the 1100 2-Door Saloon (Sedan), the 1100 3-Door Combi (Estate Wagon), and the 3-Door Combi (Panel Van).

In the mid 1950s, Carl Borgward realized that he needed to introduce sport models in his lineup for 1957. After VW introduced the Karman Ghia and Ford introduced the Thunderbird, Borgward designed the Goliath Tiger model using the regular Goliath platform. The Tiger had a 40 HP engine with dual carburetors and a higher compression ratio which produced a top speed of 84 mph compared with 78 mph claimed for the regular Goliath engine. Race car driver Dan Eames came in first in its class driving a Tiger in the 1958 500 mile stock car race in Riverside, California. The Goliath made only one pit stop.

The Tiger was added to the list of production Goliath models and sold well. Of all the Goliath models, the Tiger seems to have survived in the highest numbers in the United States.

After Goliath’s demise in 1961, Subaru introduced a 4 cylinder water cooled boxer type engine that was suspiciously like the Goliath engine. Whether the design was purchased from Borgward, or copied, or just a coincidence is a conversation among Goliath collectors to this day.

Mike Gondek’s Lloyd Alexander

In Prewar Germany, Ferdinand Porsche had designed a small inexpensive car that no one wanted to manufacture. All the European car manufactures were only interested in the large luxury cars that they knew were more profitable.

When Hitler came to power, he wanted to build a vast network of paved highways and have the German auto industry build inexpensive small economic cars for the masses just as Henry Ford had done in America. The German auto industry resisted the idea as Porsche had discovered years before. They wanted to continue producing the more profitable luxury cars, but at this time only 1 in 211 Germans owned a car.

Borgward’s prewar Lloyd was made of plywood covered with a leatherette material and had a 2-cycle under powered engine. There was a saying then in Germany: “Lloyd, the car for those who do not fear death.”

After the war, Carl Borgward was hoping to latch on to the prewar success of the small car manufacture DKW whose factory ended up in the Communist East Zone of Germany. Many of the DKW engineers and factory worker escaped from the communist zone into the West. Borgward was anxious to acquire their expertise and he hired many of the DKW engineers and assembly workers. Borgward believed that the DKW front wheel small car knowledge would be an asset for his Lloyd Motoren Werke GmbH factory in Bremen.

From 1955 to 1961, the much improved Lloyd LS600, Lloyd LP 600 and the Lloyd Alexander were produced. These cars would seat four and were air cooled, had 2 cylinder, four stroke, over head cam, 596CC engines that produced 19 HP with a 3-speed and later a 4-speed all synchromesh transmission. Suspension was front: trans leaf with rear swing axles. Brakes were hydraulic drum. The Lloyd Alexander had an all day cruising speed of 62 mph. Near the end of production the HP had been raised to 25. Production numbers for the Lloyd Alexander were 176,524 cars between 1955 and 1961 with the Volkswagen being its main competition.

There is a saying, “That it is more fun to drive a slow car fast then a fast car slow” The Lloyd was definitely a fun car to drive.

An ad for the Lloyd Alexander read:

This shapely little sedan has rightly been labeled “Germany’s wonder-car”. Built with high precision from carefully selected top –class materials it offers a surprising performance and unequaled roadability combined with utter robustness and excellent fuel economy. The comprehensive equipment besides necessities includes a number of luxuries, making the Alexander TS one of the best-equipped cars in the world. A-mile-a-minutes is the natural cruising pace for this light car with the great heart.

In an effort to streamline the Lloyd division, Borgward commissioned Italian designer Pietro Frua to design a body to fit on the chassis of the Lloyd Alexander TS. Only forty-nine 1958/59 Frua cars were built.

* * * * THE REST OF THE STORY * * * *

From the 1920s to 1961 Carl F.W. Borgward had built over a million cars. But by 1961 sales dropped and the company was left with an enormous back log of unsold cars. Although Borgward only needed a bridge loan of about 10 million DM (2.5 million dollars), the Bremer Senate refused and suppliers stopped delivering materials. No one would bail out the company and instead the company was forced into receivership. Ironically, this was handled by Johannes Semler, the founder and former chairman of the board at BMW. No surprise that many of Borgward’s engineers went to work for BMW after the closing of the plant in Bremen.